Manuals

Manuals for the K31-XXI Chassis (and related)

Minor version changes (after the decimal point) correspond to minor changes, essentially cosmetic. Major version changes (before the decimal point) correspond to big important changes.

- K31-XXI Chassis and Accessoires – Assembly Manual [PDF, 1.8MB]

Latest version: 0.7 of 2018-06-04 - K31-XXI Blitz muzzle brake — installation manual [PDF, 1.5 MB]

- Scope + mount, how to choose — guidelines

- Range cards – user manual

Historical manuals for the K31 (and related)

These were collected over the years across the Internet, and are believed to be in public domain (a notable exception to most of this site’s contents published under WTFPL); many come from the excellent SwissRifles.com source by the deeply regretted Frank [“Guisan”] van Binnendijk.

- Règlement de l’armée suisse 65.313 f “Le mousqueton 31 et les mousquetons à lunette mq. lu. 31/42 et mq. lu. 31/43. Directives pour armuriers.” ed. 1967.

- Schweizerische armee regl. 65.313 d “Der Karabiner 31 und die Zielfernrohrkarabiner 31/42 und 31/43. Anleitung für den Waffenmechaniker.” ed. 1967

- Schweizerische armee “Der Karabiner (K. 11 und K. 31). Technisches Reglement Nr. T1d” ed. 1944.

- Swiss army manual 53.101 (English translation) “Rifle (Model 11, Model 31, Scoped Model 31/42, 31/43 and 55)” ed. 1958

- Schweizerische armee reglement 53.101 d “Der Karabiner (Kar. 11, Kar. 31 und Zf. Kar.)” ed. 1961 [scanned from the original by Swisswaffen team]

- Swiss army manual 65.334 (English translation) “Rifle, Model 55 With Telescopic Sights. Arsenal instructions.” ed. 1967

- Brochure “Meine neue Waffe“, von Oberstleut. Mariotti, ed. 1937

- Brochure “Mon nouveau mousqueton“, par le Lieut.-colonel Mariotti, ed. 1941, nouvelle édition 1996 [scanned by demoniakkin]

Ballistics

Ballistic data for your favourite calculator — K31 + GP11 ord.

BC G7 (recommended): 0.274

BC G1: 0.545

Bullet length: 35 mm

Bullet weight: 11.3g / 174gr

Rifling twist: right 270 mm (~10.63″)

GP11 standard (20 century production + new batches starting from 2018)

V0: 780 m/s @ 7°C

V0 variation: 1.08 m/s / 1°C

GP11 intermezzo (2016-2017 production)

V0: 768 m/s @ 7°C

V0 variation: 0.76 m/s / 1°C

Range cards for the typical chassis setup

Sight height: 70 mm

Zero range: 100 m

Cartridge: GP11 Ord.

Click value: 0.1 mrad

[PDF DOWNLOAD GP11/20] — standard: 20 century production + new batches starting from 2018

[PDF DOWNLOAD GP11/21] — intermezzo: 2016 and 2017 production batches

(Full user manual for the rangecards. Nota bene: the manual was written for the old cards design. The new is more exhaustive, more precise, and more compact, but the logic stays essentially the same.)

Serial numbers

K31 modifications history

| 1934 | The firing pin was lightened. |

| 1935 | The receiver was made from hardened steel. |

| 1936 | The magazine was made from hardened steel. |

| 1941 | Stocks made from laminated plywood were tested, but rejected. |

| 1944 | Due to supply shortages, Chromium Molybdenum Steel was use in place of Chromium Nickel Steel on various parts. (Recognisable by “+CM” markings instead of the usual “+CN” markings) This experiment proved unsuccessful. |

| 1946 | Starting with K31 serial number 868,901, beech wood rather than walnut wood was used for making the stocks. |

Serial numbers and manufacturing dates

Source: Manufacture Dates of Swiss Schmidt-Rubin Rifles

Swiss Schmidt-Rubin rifles do not have the date of manufacture stamped on any of the rifle parts, so determining when the rifle (and mismatched parts, if any) were manufactured must be determined from the serial numbers. The definitive work on this subject, and Schmidt-Rubin rifles in general, is Die Repetiergewehre der Schweiz, Die Systeme Vetterli und Schmidt-Rubin, by Reinhart, Sallaz, and am Rhyn (ISBN 3-7276-7102-5, copyright 1991 by Verlag Stocker-Schmid AG, Dietikon-Zuerich, Schweiz), from which the tables given here are adapted.

| Year | Quantity | Serial numbers |

|---|---|---|

| 1933 | 1193 | 520010-521202 |

| 1934 | 15534 | 521203-536736 |

| 1935 | 13664 | 536737-550400 |

| 1936 | 11326 | 550401-561727 |

| 1937 | 11639 | 561728-573366 |

| 1938 | 10344 | 573367-583700 |

| 1939 | 15300 | 583701-599000 |

| 1940 | 33575 | 599001-632575 |

| 1941 | 54150 | 632576-686725 |

| 1942 | 49350 | 686726-736075 |

| 1943 | 50475 | 736076-786550 |

| 1944 | 51900 | 786551-838450 |

| 1945 | 26200 | 838451-864650 |

| 1946 | 15600 | 864651-880250 |

| 1947 | 20950 | 880251-901200 |

| 1948 | 20100 | 901201-921300 |

| 1949 | 15500 | 921301-936800 |

| 1950 | 13200 | 936801-950000 |

| 1951 | 23050 | 950001-973050 |

| 1952 | 21400 | 973051-994450 |

| 1953 | 5549 7450 |

994451-999999 215001-222450 |

| 1954 | 17150 | 222451-239600 |

| 1955 | 11250 | 239601-250850 |

| 1956 | 6400 | 250851-257250 |

| 1957 | 2950 | 257251-260200 |

| 1958 | 3130 | 260201-263330 |

| Year | Quantity | Serial numbers |

|---|---|---|

| 1934 | 16 | ? |

| 1935 | 500 | 400001-400500 |

| 1936 | 100 Zoll | 401001-401100 |

| 1937 | 150 Zoll 200 |

401101-401250 400501-400700 |

| 1938 | 150 | 400701-400850 |

| 1939 | 20 | 401501-401520 |

| 1940 | 150 530 50 50 |

400851-401000 401521-402050 402151-402220 402251-402300 |

| 1941 | 300 | 402301-402600 |

| 1942 | 650 | 402501[sic]-403150[sic] |

| 1943 | 350 | 403151-403500 |

| 1944 | 400 | 403501-403900 |

| 1945 | 600 | 403901-404500 |

| 1946 | 837 | 404501-405337 |

| 1947 | 929 30 |

405322[sic]-406250 E519767-E519796 |

| 1948 | 400 | 406251-406650 |

| 1949 | 650 | 406651-407300 |

| 1950 | 400 50 |

407301-407700 408001-408050 |

| 1951 | 300 50 |

407701-408000 408051-408100 |

| 1952 | 300 | 408101-408400 |

| 1953 | 450 50 |

408401-408850 409051-409100 |

| 1954 | 200 100 |

408851-409050 409101-409200 |

| 1955 | 450 100 |

409201-409650 410151-410250 |

| 1956 | 450 | 409651-410100 |

| 1957 | 50 300 |

410101-410150 410251-410550 |

| 1958 | 475 | 410551-411025 |

| 1959 | 425 | 411026-411450 |

| 1960 | 300 | 411451-411750 |

| 1961 | 300 | 411751-412050 |

| 1962 | 400 | 412051-412450 |

| 1963 | 50 400 |

267331-267380 412451-412850 |

| 1968-1969 | 150 | various numbers |

| 1971 | 150 50 |

269431-269580 269881-269930 |

| Stand (?) 1972 | 250 | various numbers |

Note:

Zoll – Customs service

| Serial numbers | Allocation |

|---|---|

| 215001-350000 | K31 Carbine series, ordered by KTA for KMV |

| 350001-400000 | K31 Carbine series |

| P400001-P450000 | Private K31 Carbine series |

| 450001-500000 | K31 Carbines with telescopic sights (sniper versions) |

| 500001-500200 | Trials versions |

| E519701-E519900 | Various special K31s |

| 519901-519999 | Cutaway K31s (running backwards?), last number 519970 |

| 520001-520150 | Carbine series ordered by KTA, delivered by W+F for special purposes |

| 520081-520100 | Ditto, reserved for W+F |

| 520151-999999 | Carbine series, ordered by KTA for KMV |

| after 550651 | Hardened magazine boxes |

| after 540001 | Hardened receivers |

Notes:

KTA – Kriegstechnischen Abteilung des schweizerischen Militaerdepartements

KMV – Kriegsmaterialverwaltung

W+F – Waffenfabrik

FAQ

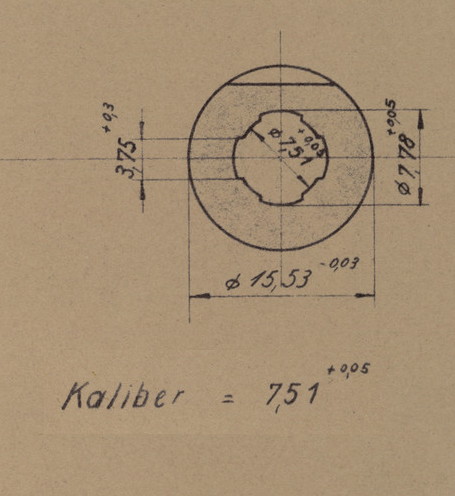

Almost any Swiss shooter owns a K31. And almost any K31 owner has an opinion as to the “perfect” bore diameter ensuring best precision.

Almost any Swiss shooter owns a K31. And almost any K31 owner has an opinion as to the “perfect” bore diameter ensuring best precision.

We have an opinion too: it does not matter. We conducted systematic tests of many K31s with Waffenfabrik barrels gauging between 7.51 and 7.54, and found no noticeable correlation between bore diameter and group size.

Furthermore, the diameter is not necessarily an indicator of how used the barrel is; we have measured bore diameters of several brand new carbines of different production lots and years, and found anything between 7.51 and 7.53 — factory new. The official specs are even more generous; according to the Waffenfabrik K31 blueprints, the nominal calibre is 7.51, but production tolerances are ok up to 7.56.

This being said, gauging is useful: barrels which did not have the same diameter over the whole length (one side larger than the other) showed inferior precision compared to fully uniform barrels. Also, barrels gauging 7.55 or above were usually “tired”, and precision started to suffer.

This last remark is only valid for K31s only with Waffenfabrik barrels. Hämmerli barrels (rare, recognisable by the “hammer” marking) gauge larger from factory, and at 7.55 usually show totally convincing precision. Also, standard and free ISSF/CISM 300m carbines (which are usually very precise) chambered for 7.55×55 as a rule are built on .30 cal barrels (the same as for .308 Win or .300 Win Mag), and gauge significantly larger — 7.55 or 7.56 factory new.

In summary: for a Waffenfabrik-barrelled K31, make sure the diameter is below 7.55 and is uniform across the length (same on both the chamber and the business ends). Beyond that — only the target can tell the ultimate truth.

[link]

Short answer: it depends on the scope.

The long answer is at the “Scope + mount, how to choose” page.

The army manual specifies median (50%) rectangle of 4×6 cm at 300 m at a shooting bench using ordnance GP11 ammo. In other words, at this distance 95% of impacts should land in a 12×18 cm rectangle.

Although many K31 barrels are potentially capable to do better than that, the numbers correspond to a shooting bench, without a real shooter behind the rifle. This being said, with a good optical scope (to minimise aiming errors) and a good ergonomics chassis (to minimise shooter errors / “flyer” shots), it is entirely possible to approach these theoretical limits.

In practice, a good shooter behind a well-equipped carbine, keeping a slow rate of fire (not more than 1 shot per minute, in order not to overheat the barrel), at 300 m can expect 10-shot series of 96 to 98 out of 100 on a FST A10 target. At systematic 98 points or better, one can consider the barrel to be very, very good.

[link]